Recent Advancements In Sustainable Hydrogels for Sensing, Temperature Response, and Catalytic Applications

Abstract

Over

the previous few decades, the interest of chemists has shifted toward material

chemistry. The main reason behind this philosophical shift is the straitened

properties and dearth of wanted materials to fulfill the surfeited demand.

Material chemistry develops intellectual thoughts to manipulate the smart

materials of promising, desirable characteristics to suit further use.

Improvements from proffer solid to polymer and molecular to nanomaterial

unfurled its scope towards catalysts, sensors, molecular transporters, and

filters with the capability of immense scientific, social, and pecuniary

impact. Nowadays nanomaterials found profound exploitation at the industrial,

analytical, and domestic levels.

Keywords: Hydrogel, Optical

property, Sensing, Catalytic activity, Temperature response.

1.

Gel

A gel consists of two constituents, in which some cross-linkers

three-dimensionally interconnect the polymer chains. This structurally complex

3D network material (component 1) forms a rigid network, accommodating a

relatively large proportion of fluid (component 2). Both

inorganic and organic molecules can act as precursors for gelation. Depending

upon the composition of the gel, the forces of interaction for cross-linking

may differ from primary interaction to secondary interaction1-3. Gels are mushy materials Seemed solid

but are Susceptible to undergoing large contortion in response to external

stimuli4.

Polymer gel consists of a

three-dimensional network of elastic polymer chains including fluid between the

interstitial pores of the 3D network5.

Polymer gel exists in two phases swollen and collapsed, volume transition

between these phases can occur continuously or discontinuously6. Broadly polymer gel can be classified

into two classes based on dispersion medium, Aerogels, and Lyogels. In

aerogels, the dispersion medium is gas, while gels containing liquid as a

dispersion medium are known as lyogels7,8.

Lyogels containing non-polar liquid between their interstitial spaces are

called organo-gels, these gels tend to swell in the organic solvent. If

interstitial spaces are occupied by water, then they are known as hydrogels9.

Hydrogels are a 3D polymer network with a sufficient degree of

cross-linking, they are capable of absorbing and retaining a large amount of

water or aqueous solution (hundreds to thousands of times of its mass) without

dissolution10. Their degree of

flexibility is comparable to that of natural tissue due to their large

water-retaining capacity. The water-retaining proficiency of hydrogel arises

due to the hydrophilic functional group affixed to the polymeric backbone;

their resistance to dissolution is due to cross-linking between the polymer

chains11. Nonetheless, hydrogels contain large water content but

they show the characteristics of both solids and liquids, the transport of

small molecules and ions across the hydrogel by diffusion is analogous to

liquids, meanwhile at the macroscopic level, they exhibit the characteristics

of solids; preserve their shape and show mechanical strength like solids12. These Characteristics make them an

appropriate candidate for drug delivery, tissue engineering13, contact lens14, sensor15,

and catalysis16. A mesh is a

solid portion of a 3-D network of crosslinked polymer chains as shown in (Figure

1)17

Figure1:

Structural chemistry of a hydrogel,

“Hydrogels can be classified as follows”11.

2.1.

Hydrogels based on source

On the base of origin, hydrogels are

categorized into two groups. Natural hydrogels i.e. polysaccharides (like

hyaluronic acid, alginate, cellulose, and chitosan), proteins (e.g. collagen

and gelatin), DNA, etc3.

Synthetic hydrogels are fabricated by using various types of precursors (one or

more than one type)18. Poly

(NIPAM-co-2 HEA)19, poly (N,

N′-diethyl aminoethyl methacrylate), poly (N-isopropyl acrylamide)20, poly (N‐isopropyl acrylamide‐co‐vinyl

phosphonic acid)21 are some

examples of synthetic polymers.

2.2.

Hydrogels based on polymeric composition

On the base of the polymeric

composition, there are three classes of hydrogels.

2.2.1. Homopolymer gels: Those hydrogels which are synthesized by using

a single type of monomer are known as homopolymer hydrogels22. The Structural framework depends upon

the nature of the monomer, the nature of the cross-linker, and the type of

polymerization technique used for its fabrication. Polyethylene and

glycol-based hydrogels are examples of homopolymer gels. These types of

polymers contain only one type of monomer in their polymeric network, so their

properties are limited23.

2.2.2. Copolymer hydrogels: Hydrogels that are fabricated by using more

than one type of monomer are termed copolymeric hydrogels; usually, one type of

monomer is hydrophilic. Depending upon the type of precursors and reaction

conditions monomers can be arranged to form different configurations (i.e.

random, alternate, or block) to form a polymeric network24. Due to their multi-responsive nature,

they have several biomedical applications e.g. drug delivery25.

2.2.3. Multi polymer hydrogel: Multi-polymer hydrogels are fabricated by

using three or more types of monomers by polymerization technique and

cross-linking reaction. Poly (acrylic acid-2-hydroxy ethyl

methacrylate)/gelatin hydrogel is an example of a multi-polymer hydrogel. They

are multi-responsive due to the presence of more than one type of monomer26.

2.3.

Semi-interpenetrating polymeric hydrogels

In these types of hydrogels, one linear

polymer penetrates other cross-linked polymeric networks without forming any

other chemical bond between them. Due to the absence of an interpenetrating

network, they retain the rapid pH and temperature-responsive behavior, but they

can adjust their pore size and sluggish drug delivery. One example of this type

of gel is the entrapment of poly allyl-ammonium chloride in acrylamide /acrylic

acid copolymeric hydrogel. The resulting hydrogel contains both covalent as well

as ionic bonds, the covalent bond is responsible for the stability of the 3-D

network and the ionic bond is responsible for higher mechanical strength and

pH-responsive behavior27. These

types of gels have a large no of applications in drug delivery, for dyes, and

heavy metal separation28.

2.4.

Interpenetrating hydrogels

Such types of hydrogels are synthesized by intimate cross-linking

of two independent polymers, at least one component is the cross-linked polymer

and the other component is non-crosslinked11, This

is fabricated by immersing an already synthesized hydrogel into the solution of

the initiator and precursors. The interlocked cross-linked polymeric component

is responsible for its stability and morphology. The component polymer of such

hydrogels cannot be separated unless the chemical bond between them is broken29. The main advantage of this method is

that we can produce stiff and dense hydrogel metrics with desirable physical

and mechanical properties. The kinetics of drug delivery can be controlled by

tuning the pore size and surface morphology30.

2.5.

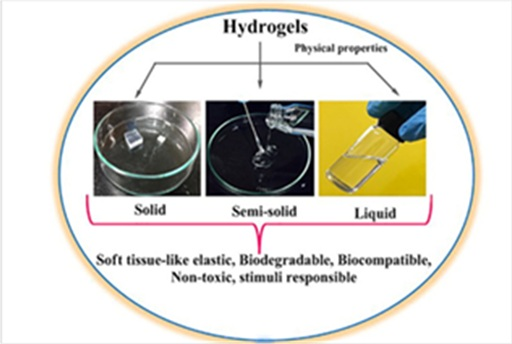

Classification based on physical appearance

Based on the physical appearance, there are three classes of

hydrogel, as shown in (Figure 2)31

Figure

2: Physical properties of hydrogels.

2.5.1. Solid hydrogels: Those hydrogels that exist in a solid state at

room temperature are known as solid hydrogels. They can shrink and swell in

liquids: like water, biological fluids, and buffer solutions. Depending upon

the interest in using inorganic metal partials inside these types of hydrogels,

they can glow; which gives prominent electrical, magnetic, and optical

properties31.

2.5.2. Semi-solid hydrogels: These types of hydrogels possess strong

adhesive interaction with other types of interaction (hydrogen bonding, Vander

walls interactions, and electrostatic interaction) and a network of soft

tissues. Two different kinds of materials are used to fabricate them. One of

these must be natural like plant gum, poly (N vinyl Pyrrolidone),

Polycarbphhil, Carbopol, etc32.

The molecular weight of selecting polymeric material must be ≥ 100, which

enhances the flexibility of hydrogel. Due to bio-adhesive properties, these

hydrogels are named bio adhesives33.

2.5.3. Liquid hydrogels: Such hydrogels are in a liquid state at room

temperature, they exist as soft tissue-like elastic material at a specific

temperature, and they are easily fabricated34.

Due to their self-adjustment in their pore size, in response to the

environmental condition, they have a diverse number of applications: e.g.

organic and inorganic drug delivery processes. Due to their hydrophilic nature,

it is easy to incorporate protein inside them, so they are injected inside

living organisms for Vivo applications35.

2.6.

Classification based on type of cross-linking

There are three types of classes Based

on this classification, physically cross-linked, chemically cross-linked, and

Double-Network Hydrogels36.

2.6.1. Reversible or physically cross-linked hydrogels: In these types of

hydrogels, polymeric chains interconnect by molecular entanglement or secondary

forces: like hydrogen bonding or ionic interactions. The central role in

forming chemical interactions is hydrophobic interactions. Depending on the

environmental conditions such as pH and temperature, they can dissolve37,38. In

recent years, scientists have been interested in preparing physically

cross-linked hydrogels. The main advantage of this type of hydrogel is that

there is no need to use cross-linking agents. Cross-linking agents do not only

affect the integrity of hydrogels but some are sometimes also toxic, therefore,

must be removed before further use37.

2.6.2. Permanent or chemically cross-linked hydrogels: In these types of

hydrogels, the polymeric chains interconnect by a permanent covalent bond, so

they are unable to dissolve. They are stable39.

Depending upon the nature of functional groups present in the 3-D networks,

they can be charged or neutral. They may show a change in their shape in

response to the external electric field and other stimuli40. They have more mechanical Strength and

degradation time as compared to physically cross-linked hydrogels31.

2.6.3. Double-network hydrogels: In these types of hydrogels, there are two

types of cross-linking (both physical and chemical) are present. It overcomes

the disadvantages of using either physically cross-linked or chemically

cross-linked hydrogels. A recently reported graphene-polymer composite with

excellent mechanical properties and self-healing capability is an example of a

dual-network hydrogel37.

2.7.

Classification based upon stimuli response

Stimuli-responsive hydrogels show an unexpected change in growth action, mechanical strength, and structural network in response to external stimuli: so, they are known as Smart hydrogels, As shown in schematic (Figure 3)41 Light, Temperature, Pressure, mechanical stress, and intensity of various sources of energy are examples of physical stimuli.

Figure

3:

Stimuli-responsive behavior of hydrogels.

These stimuli are responsible for the change in the interaction

between the components of gels at specific critical points. Another type is

chemical stimuli, including pH, ionic factors, and chemical reagents: they are

responsible for the change in the interaction between the solvent and component

of gels and within gel at the molecular level42.

Many multi-responsive hydrogels are also reported, like a polyacrylic

acid-co-polyvinyl sulfonic acid-based hydrogel43.

2.7.1. pH-responsive hydrogels

Such polymeric gel, which contains the ionic

pendant groups, is pH-responsive. In response to the environmental conditions,

these groups pick and lose protons. They show a sudden dramatic change in their

ionization (pKa and pKb) at a specific pH, so they show

sudden volume change at a certain pH. This volume transition occurs due to the

generation of the electrostatic force of repulsion between the ionized groups,

which creates osmotic pressure for swellings. Both cationic and anionic

hydrogel show pH-responsive behavior. Anionic Hydrogels are made up of monomers

containing functional groups (like carboxylic, sulphonic, and phosphonic),

which donate protons above pKa, creating the same charge at

different sites within the hydrogel. But cationic hydrogels contain functional

groups like amines where protonation occurs below PCB; this leads to the

production of similar charges at different sites within the 3-D network, which

is responsible for volume transition44.

The degree of swelling is controlled by controlling the amount of cross-linker

during the preparation of hydrogel, ionic charge, pKa, or pKb

value of the ionizable groups, hydrophobicity, hydrophilicity, and degree of

ionization45.

2.7.2. Temperature-responsive hydrogels

Such

hydrogels that can shrink or swell in response to the temperature of

surrounding fluids are known as temperature-responsive hydrogels46. Chitosan-based copolymer hydrogels

extensively studied temperature-responsive hydrogels, like methylcellulose,

hydroxypropyl methylcellulose, and NIPAM. Poly (NIPAM) shows a sharp phase

transition at a temperature of 34.43 °C in water. P (NIPAM)’s LCT can be

altered by the copolymerization of other monomers. It can be increased by

copolymerization with hydrophilic monomers and can be decreased by

copolymerization with hydrophobic monomers. However, the grafting of such a

functional group does not have any appreciable effect on LCT. There are three

types of temperature-responsive hydrogels37.

2.7.2.1. Positive temperature hydrogels

They are known as upper

critical solution temperature (UCT) hydrogels. They are in a swell state at a

temperature above their UCT, but they exist in a shrinking state at a

temperature below their UCT. So as the temperature becomes below then the UCT

dehydration occurs and they release water from their interstitial pores. At

elevated temperatures, the breakage of hydrogen bonds occurs, so this creates

the same charge on different sites. As a result, the positive temperature

hydrogel exists in the maximum swelling state above its UCT20.

2.7.2.2. Negative temperature hydrogels

Such types of hydrogels

exist in the swell state, at a temperature below the LCT; and as the

temperature rises above its LCT, it shrinks. The most important parameter for

such types of hydrogels is LCT. LCT is controlled in no of ways: by changing

the solvent composition, by mixing a small amount of ionic copolymer, or by

changing the hydrophobic and hydrophilic cotenant polymeric hydrogels47. Their 3-D network contains both

hydrophobic and hydrophilic parts. At a temperature below the LCT, the

hydrophilic part interacts with water or fluid by forming a hydrogen bond. Due

to solvation, the swelling will increase. While at the temperature above the

LCT, the hydrophobic interaction between various parts of the hydrogel becomes

dominant; meanwhile, the hydrogen bonding becomes weaker. So, the hydrogel will

exist in shrink form at a temperature above its LCT.

2.7.2.3. Thermoreversible hydrogel

Such type of hydrogels has the same kind of

composition as that of positive temperature hydrogels and negative temperature

hydrogels. However, they differ in their bond type from the previous two types

of thermoresponsive hydrogels. Instead of covalently cross-linked polymer

chains that show volume change transition, they undergo a sole gel phase

transition. Different types of hydrophobic and hydrophilic interactions are

responsible for the abrupt change in their volume. In the swollen state, the

water molecules organize around the hydrophobic component of the gel (as in the

iceberg) by forming a hydrogen bond with the hydrophilic part of the gel. At

CST, the hydrophobic and hydrophilic interaction between polymer-polymer chains

and solvent-solvent becomes greater than the polymer-solvent interaction. So,

they exist in shrink form at CST37,48.

Hydrogels can be synthesized either from

natural or synthetic polymers. The chemical strength of synthetic polymers is

greater, and their degradation process is slow compared to natural polymers.

The greater durability of synthetic polymers is due to their greater mechanical

strength. These two properties are optimized during synthesis according to the

desired use. Their synthetic techniques are similar to those techniques, which

are used for the synthesis of cross-linked polymers. The schematic diagram for

the synthesis of hydrogel is shown in (Figure 4)11

Figure

4:

Schematic diagram of hydrogel preparation.

3.1. Bulk polymerization

It is the simplest method of synthesis,

in which one more type of monomer polymerizes to give the hydrogel of desired

properties. The type of initiators used depends upon the nature of monomers.

The rate of bulk polymerization is very high. There is a sharp increase in

viscosity as the reaction proceeds, and heat dissipation is a big problem of

this technique. These problems can be minimized, by controlling the rate of

polymerization. The end product of bulk polymerization is the glassy, hard, and

transparent homogenous gel. It swells to form soft and flexible materials when

immersed in water.

3.2. Solution polymerization

In solution polymerization, the mixture

of (neutral or ionic) monomers and cross-linkers is dissolved in a suitable

solvent. The redox initiator is used. The polymerization is initiated either

thermally or by irradiating UV light. After completion of the reaction: the

unreacted monomers, oligomers, initiator molecules, and other impurities are

removed by washing with distal water or DIW. The main advantage of this

technique over bulk polymerization is the use of a solvent that acts as a heat

sink. The most common solvents used in this technique are water, ethanol, a

mixture of water or ethanol, and benzyl alcohol. For the removal of the

synthetic solvent, the prepared gel may swell in water.

3.3. Suspension polymerization/Inverse

suspension polymerization

The end product of this method of

synthesis resulted in the form of powder or beads, so no further grinding is

required. “The process in which water-in-oil system (W/O) is used is termed an

inverse suspension polymerization, while in suspension polymerization process

oil-in-water (O/W) is used.” Suspension polymerization is a commonly used

technique. During this process, the homo genius mixture of monomers and

initiator molecules is dispersed in the organic phase. The addition of a

suspending agent and continuous agitation is necessary because dispersion is

not thermodynamically stable.

3.4. Suspension by irradiation

If we have to produce the hydrogel from

saturated compounds, the reaction is initiated by irradiating with high

energy/ionizing radiations like gamma rays or beams of electrons. This

irradiation is responsible for the production of free radicals on the polymer

chain and the radiolysis of water. The hydroxyl radicals (product of radiolysis

of water), and small fragments radicals (produced by the hemolytic cleavage of

a polymer chain) may attack the polymer chains to produce macro-free radicals.

These macro radicals may combine to produce a 3-D cross-linked network system.

The main superiority of this technique over the chemically initiated method is

the production of relatively pure and initiator-free hydrogels; i.e. poly

(vinyl alcohols), Poly (acrylic acid), and poly (ethylene glycol) are

cross-linked by this method.

4.

Nanotechnology

The concept of nanotechnology was given

by Nobel laureate Richard P. Feynman in his famous lecture “There are Plenty of

Rooms at the Bottom” in 1960. The word Nano originated from Latin and means

Dwarf. With the advancement in nanotechnology, a variety of materials is

synthesized. “Nanomaterial is such a substance which has at least one dimension

in the nanometer range’. There are many types of classification of nanomaterial49.

4.1.

Classification based on dimensionality

According to this type of

classification; basically, there are four types of nanomaterial: i.e. 0D, 1D,

2D, and 3D. Dimensionality is generally represented by the notation “kD/mn”.

The value of k represents the dimensionality of overall materials, while the

value of l, m, and n designates the dimensionality of the building blocks of

the overall material. The value of k must be equal to or greater than the value

of l, m, and n. According to this type of class, there are 36 types of

nanomaterials50.

4.2.

Classification based upon composition

There is another type of classification,

“which is according to the chemical composition of constituents51."

4.2.1. Metal-based nanomaterials

Metal-based nanomaterials may be pure metal or metal alloys51. Silver-based nanomaterials have

catalytic, diagnostic, conductive, antibacterial, and optical applications.

Copper-based partials and their assemblies are used, as catalysts, electrical

conductors, thermal conductors, antibacterial agents, and lubricant additives51.

The gold-based nanostructure is exploited for drug delivery systems and

specialized alloys, medical testing and cancer detections, dissipation of heat,

and fuel cells. Due to their low density and high heat resistance, the

nanostructures based on Al-Mg alloy, Mg, Al, and titanium are employed in

aerospace technology52. Because

of its unique magnetic properties, the Fe-Si-B alloy is used for the

fabrication of electronic devices53.

Iron, Platinum, and palladium nanoparticles are used as catalysts54.

4.2.2. Metal oxide-based nanomaterials

Titanium oxide, cerium

oxide, and zinc oxide nanoparticles are used as sun screeners in cosmetics

products due to filter UV radiation. Nano-silica has good optical absorption

ability and photoluminescence and is also used in drug delivery systems. Nano alumina

coating acts as an abrasion resister acts as a catalyst and is termly

conductive. Depending on the nature of iron oxide, it might be used in the

biomedical field, as an ion exchanger, or in the fabrication of electronic

structures. The iron oxide nanomaterials may be employed as pigments or might

be for the purification of water55-57.

4.2.3. Semiconductor nanomaterials

At the nanoscale, the properties of materials

are owned by quantum mechanics58.

Nano silicon has applications in solar cells and the biological field and

photovoltaic etc. gallium nitride and gallium arsenide at nanoscale use in

photovoltaic and in the production of light-emitting diodes.

4.2.4. Nanomaterial including silicates, carbonates, and nitrates

Clay (a nano silicate)

can take the shape of a nanotube or nanoplates. Clay may be employed as filler

in composites to enhance its mechanical properties, improve electrical

conductance, and increase resistance against heat or flame. Nanoparticles of

silicon nitrides might be used to decrease the possibility of propagation of

the crack. Zeolite at the nanoscale has catalytic applications and may be used

in membrane fabrications59.

4.2.5. Carbon-based nanomaterials

Carbon-based nanomaterials represent one of

the best classes of nanomaterials. Graphene is a one-atom-thick sheet made up

of carbon. It has promising applications but its industrial synthesis is under

development60. Grephen’s

self-alignment in cylindrical form due to wander wall forces from carbon

nanotubes61. Carbon nanofibers

are also folded graphene but without perfect arrangements. Fullerenes are

spherical, formed by the folding of graphene. Carbon black is amorphous carbon

particles left as a byproduct of incomplete combustion62,63.

4.2.5.1. Nano polymers: Nano capsules and nanospheres are examples of

nano polymers. They have an important use in drug delivery64.

4.2.5.2. Dendrimers: There are two parts of dendrimers, one is an

internal core and the other is the outer branch. The branches can be modified

according to requirements. They are important candidates for drug delivery65.

4.3.

Classification based upon origin

There are two types of nanomaterials, synthetic and natural.

Naturally occurring nanomaterials are either synthesized within living bodies

or by anthropogenic actions outside the bodies. They are found everywhere:

inside the earth's crust, in oceans, on the earth's surface, or in the

atmosphere. Human DNA is an excellent example of naturally occurring

nanomaterials. Numerous varieties of nanomaterials are synthesized in

laboratories and on a commercial scale66.

There are two techniques adopted for the synthesis of

nanoparticles, “termed as bottom-up method and top to the down method,” as

shown in schematic (Figure 5)67

A relatively new technique available only in modern laboratories,” the Bottom

to Bottom” approach is also adopted51.

Figure

5:

Schematic diagram of top-down and bottom-up synthesis methods.

5.1.

Top-down method

In the "top-down method," we

start with a substance in bulk form and end with nanoscale objects by applying

either mechanical stress (grinding, milling, or etching); or by using some

chemical agents. The most popular physical method for the top-down approach is

lithography, and the other relatively new is electric erosion68. It's an easy and cheaper method, but it

has many shortcomings; the end product is polydisperse and may have defects in

its morphology51.

5.2.

Bottom up method

In this approach of fabrication, we

start with atoms or molecules and end with nano-scale objects. During this

technique, the first step is the formation of stable nuclei, and the next step

is growth. By controlling the growth, we can control the overall size of the

resulting nano object. By controlling the growth at different sites, we can

control the morphology of results from materials69.

A microgel containing metal particles inside their interstitial

pores is known as a hybrid microgel. The schematic diagram for the synthesis of

hybrid microgel is shown in (Figure 1.6). The nanoparticle is the

aggregation of bounded atoms having a three-dimensional radius within the range

of a nanometer. The nanoparticles are highly reactive, having a high

surface-to-volume ratio and high surface energy. Due to high interfacial activities,

they tend to react with contaminants in water, gas, and the earth. So, they are

beneficial candidates for controlling environmental pollution. Due to their

unstable nature, they have great difficulties in their mass transport. Their

separation, reusability, and prevention from agglomeration are difficult tasks.

They may be risky for human health and the ecosystem. These risks and

difficulties can be minimized; by their incorporation into the gel or other

porous material70. Such hybrid

gels are known as smart materials due to their stimuli-responsive nature71.

Figure 6:

Hybrid microgel enhanced physical and chemical properties.

6.1. Responsive hybrid microgels

The hybrid gel may respond to different

stimuli (like pH and temperature) depending on its chemical composition. The

partial size may vary in response to environmental conditions72.

6.1.1. Temperature-responsive hybrid

microgels

Depending upon the

composition of the microgel, their hydrodynamic volume may increase or decrease

with the change of temperature of the medium. The most studied

temperature-responsive hybrid gels are poly (NIPAM) and PVC-based. The

temperature at which the hybrid system shows abrupt change is known as the VPTT

of that hybrid system. NIPAM-based microgel shows a decrease in hydrodynamic

radius with an increase in medium temperature.

6.1.2. Glucose-responsive hybrid microgels

Sliver NP’s incorporated hybrid gel

containing Phenyl boric acid in their host polymeric gel is glucose-responsive.

Poly (3-Acrylamidephenylboronic-co-acrylic acid)-Ag NPs show an increase in

hydrodynamic volume in response to a rise in Glucose concentration of the

medium73.

6.1.3. pH-responsive hybrid microgels

Such hybrid gel shows the change in

hydrodynamic radius in response to the alteration of the medium’s pH. Such a

system contains ionizable functional groups in the polymeric gel. The hybrid

gels containing amino groups in their 3-D polymeric network exhibit an increase

in volume due to the protonation of the amino group. So, they exist in a

swollen state when the pH of the medium is high. Gels containing carboxylic

groups in their 3-D network show an increase in volume at pH ≥ PKA of ionizing

species.

6.1.4. Ionic-responsive hybrid microgels

Such hybrid gels respond to the change

in the concentration of ions in the medium. They are responsive to different

electrolytes like KCl and CdCl2. Investigation shows that VPTT moves

towards the lower temperature, as the salt concentration of the medium

increases.

6.1.5. Multi-responsive hybrid microgel

Those hybrid gels, which can respond to

more than one stimulus, are known as multi-responsive hybrid gels, as shown in (Figure

7).

Figure

7:

Multi-responsive behavior of silver-embedded microgels towards external

stimuli.

They contain more than one type of monomer in their 3-D structure.

For example, Ag NPs loaded poly (N-isopropyl acrylamide-co-acrylamide-co-vinyl

phenylboronic acid) gel is pH, Glucose concentration, and

temperature-responsive. Poly (N-isopropyl acrylamide-co-vinylphenylboronic

acid), and poly (acrylamide-co-vinylphenylboronic acid) show sensitivity toward

glucose concentration, temperature, and pH. At a given pH of the medium, they

show increases in volume with the increase in the concentration of the medium,

because more glucose moves inside.

7. In situ synthesis of metal nano

particles

For "in situ synthesis," the ions of metals are loaded inside porous material; pours material is a gel for hybrid gel synthesis. Then the calculated amount of some reducing agent is added for the synthesis of zero-valent metal nanoparticles. The schematic diagram for the Situ synthesis of silver particles is shown in (Figure 8)74 Such a metal ion-loaded system may interact with Se2-, OH-1, or S2- depending upon the required composition of the metal nanoparticle75,76.

Figure

8:

Fabrication of Silver nanoparticles inside microgel by in-situ reduction

method.

Other methodologies of in situ synthesis are mixing the

nanoparticle and precursor of the host polymeric system. Then the

polymerization is preceded by the desired condition to make a hybrid system77. The other approach is mixing the

precursor of both “metal nanoparticles and host polymer” in a suitable solvent78.

Silver gives a white and lustrous appearance; these soft

transition elements possess excellent catalytic and thermal properties. Silver

nanoparticles may be employed as a sensor and as antibacterial agents79. They tend to agglomerate because of high

interfacial activity. "Microgel provides stability to silver particles due

to different anchoring functional groups; moreover, we can tune the size of the

particle inside the gel80."

8.1. Applications of silver embedded

hybrid microgels

8.1.1. Catalytic applications:

Because of the high surface-to-volume ratio, the silver NPs are an efficient

catalyst. However, due to their high interfacial activities, smaller NPs

aggregate to form bigger partials, so as a result, their catalytic activity

decreases. Many substances like dendrimers, surfactants, and polymer brushes

are used as a stabilizer for Ag NPs. The silver NPs stabilized by these

substances cannot be reused. Moreover, there is a greater chance of poisoning

and contamination of catalysts during the catalytic reaction. The Ag NP’s

embedded microgel is a very impressive microreactor for catalysis. Their

catalytic activity is many times faster than other systems. The inert polymeric

network eases the diffusion of reactants toward the Ag NP’s surface and allows

the outward diffusions of the product. Their catalytic activity can be tuned by

changing external stimuli.

8.1.2. Biomedical applications:

Some stimuli-responsive Ag NPs encapsulated hydrogels are used for blood

glucose detection and controlled delivery of insulin. The fluorescence

intensity of some biomolecules is very low, so there is a problem with their

detection by fluorescence analysis. The coupling of such molecules with Ag NP’s

loaded microgel can enhance their fluorescence intensity. The detection of

porphyrin by metal-enhanced fluorescence effect is reported in the literature.

It is used for cell imaging.

8.1.3. Applications in semiconductor

devices:

When Ag NP’s embedded hybrid gel is encapsulated in a hydrophobic shell, a such

hybrid gel is no more sensitive to stimuli except light. Hybrid gel exists in a

collapsed state at high temperatures, so the distance between the NPs

decreased. When light is irradiated, the reflectance increases because there

are no spaces through which light can pass. Their suspension may be used as

photonic crystals in different fields.

8.1.4.

Calorimetric sensing: In clinical

procedures, pharmaceutical industries, food industries, and environmental

analysis, hydrogen peroxide determination is very important81. Several methodologies like the

chromatographic technique82,

titrimetric analysis83, chemiluminescenc84, fluorometry85,

Spectrophotometric analysis86,

and electrochemistry87 are used

for (hydrogen peroxide) analysis. These conventional methods are usually

time-consuming, difficult, and complicated. With the advancement of

nanotechnology, the most commonly used electrochemistry technique is improved

by replacing enzyme-based biosensors with nanoparticle-based sensors. Because

of efficient catalysis, excellent surface-enhanced Raman scattering, low

toxicity, and biocompatibility the Ag NPs earned significant fame in hydrogen

peroxide sensing88,89. The silver-embedded three-dimensional

network system is an efficient and cheap candidate for hydrogen peroxide

sensing90.

8.1.5. Optical properties: In response to external stimuli, the hybrid

gel can swell and de-swell. As a result, a change in surrounding the effect of

solvent, refractive index of solvent, interparticle distance of embedded

particle distance, and surface effect changes. So, by changing the condition of

the surrounding medium, we can change the surface Plasmon band91.

9. Conclusion

Recent advancements in sustainable hydrogels have significantly

expanded their potential in sensing, temperature-responsive systems, and

catalytic applications. Innovations in biodegradable polymers, bio-based

materials, and green synthesis methods have improved hydrogel performance while

minimizing environmental impact. These materials now exhibit enhanced

sensitivity, tunable responsiveness, and improved catalytic efficiency, making

them highly attractive for diverse applications, including biosensing, drug

delivery, and environmental remediation. Despite these achievements, challenges

such as scalability, long-term stability, and cost-effective production remain.

Future research should optimize hydrogel properties through advanced material

design and integrate them with emerging technologies such as nanomaterials and

smart devices. By addressing these challenges, sustainable hydrogels will

continue to play a crucial role in developing eco-friendly and high-performance

functional materials.

10. Acknowledgment

We Acknowledge this article to a brave leader (Imran Khan) of

Pakistan.

11. Declaration of competing interest

The authors declare that they have no known competing financial

interests or personal relationships that could have appeared to influence the

work reported in this paper.

12. Data availability

Data will be made available on request.

13. References

1.Memon IA, Xudong L, Xiaoqing C, et al. A review of

electro-stimulated gels and their applications: Present state and future

perspectives, in: J Mater Sci, 2019: 109852.

4.Osada Y, Gong JP.

Soft and wet materials: polymer gels, Adv. Mater, 1998;10: 827-837.

5. Ahn SK, Kasi RM,

Kim SC, et al. Stimuli-responsive polymer gels. Soft Matter, 2008;4: 1151-1157.

6. Annaka M, Tanaka T. Multiple phases of polymer

gels. Nature, 1992;355: 430-432.

9.Nabi SAA, Sheraz MA, Ahmed S, et al. Pharmaceutical

Gels: A Review. J Pharm. Pharm Sci, 2016;4: 40-48.

17. Gibas I, Janik H.

Synthetic polymer hydrogels for biomedical applications, 2010.

18.Gyles DA, Castro LD, Silva Jr JOC, et al. A review of

the designs and prominent biomedical advances of natural and synthetic hydrogel

formulations. Eur Polym J, 2017;88: 373-392.

20.Qizu Y, Park K.

Environment-sensitive hydrogels for drug delivery. J Mater Sci, 2001;53:

321-339.

30. de Britto D,

Campana-Filho SP. Kinetics of the thermal degradation of chitosan.

Thermochimica acta, 2007;465: 73-82.

46. Richter A.

Hydrogels for actuators, in: Hydrogel sensors and actuators. Springer, 2009:

221-248.

52. Morris DG. The

origins of strengthening in nanostructured metals and alloys, 2010.

56. Dioxide NT. State

of the Science Literature Review: Nano Titanium Dioxide Environmental Matters.

64. Rangasamy M. Nano

technology: a review. J Appl Pharm Sci, 2011;1: 8-16.

65. Khopde A. Dendrimer as a potential delivery system for

bioactive In: Jain NK, editor. Advances in controlled and novel drug delivery.

CBS publisher, 2001.

68. Ramsden JJ.

Nanotechnology: an Introduction. William Andrew, 2016.

70. Zhao X, Lv L, Pan B, et al. Polymer-supported

nanocomposites for environmental application: a review. Chem Eng J, 2011;170:

381-394.

71. Zhang Y, Gu W, Xu H, et al. Facile fabrication of hybrid

nanoparticles surface grafted with multi‐responsive polymer brushes via block

copolymer micellization and self‐catalyzed core gelation. J Appl Polym Sci,

2008;46: 2379-2389.

72.Liu YY, Liu XY, Yang JM, et al. Investigation of Ag

nanoparticles loading temperature responsive hybrid microgels and their

temperature controlled catalytic activity. Colloids Surf A Physicochem. Eng

Asp, 2012;393: 105-110.

74.Begum R, Naseem K, Farooqi ZH. A review of responsive

hybrid microgels fabricated with silver nanoparticles: synthesis,

classification, characterization and applications. J Solgel Sci Technol,

2016;77: 497-515.

84.Lei W, Dürkop

A, Lin Z, et al. Detection of hydrogen peroxide in river water via a

microplate luminescence assay with time-resolved (“gated”) detection. Mikrochim

Acta, 2003;143: 269-274.